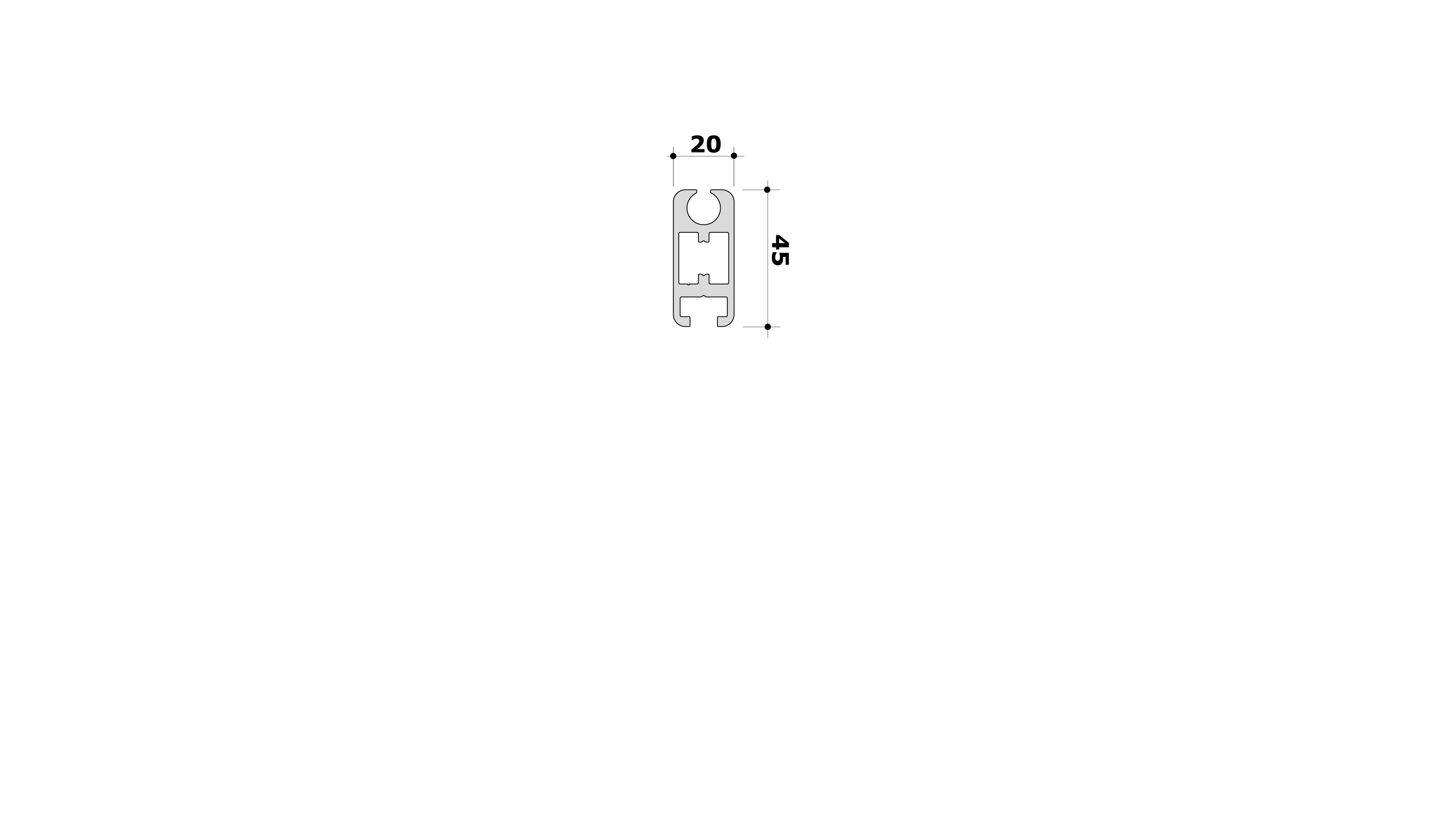

The profile for the good old way of putting up banners and flags, usually for mounting by means of hemstitch and keder tube, rod, or chain. A special feature of this way of mounting is the fact that both sides of the fabric can be visible sides.

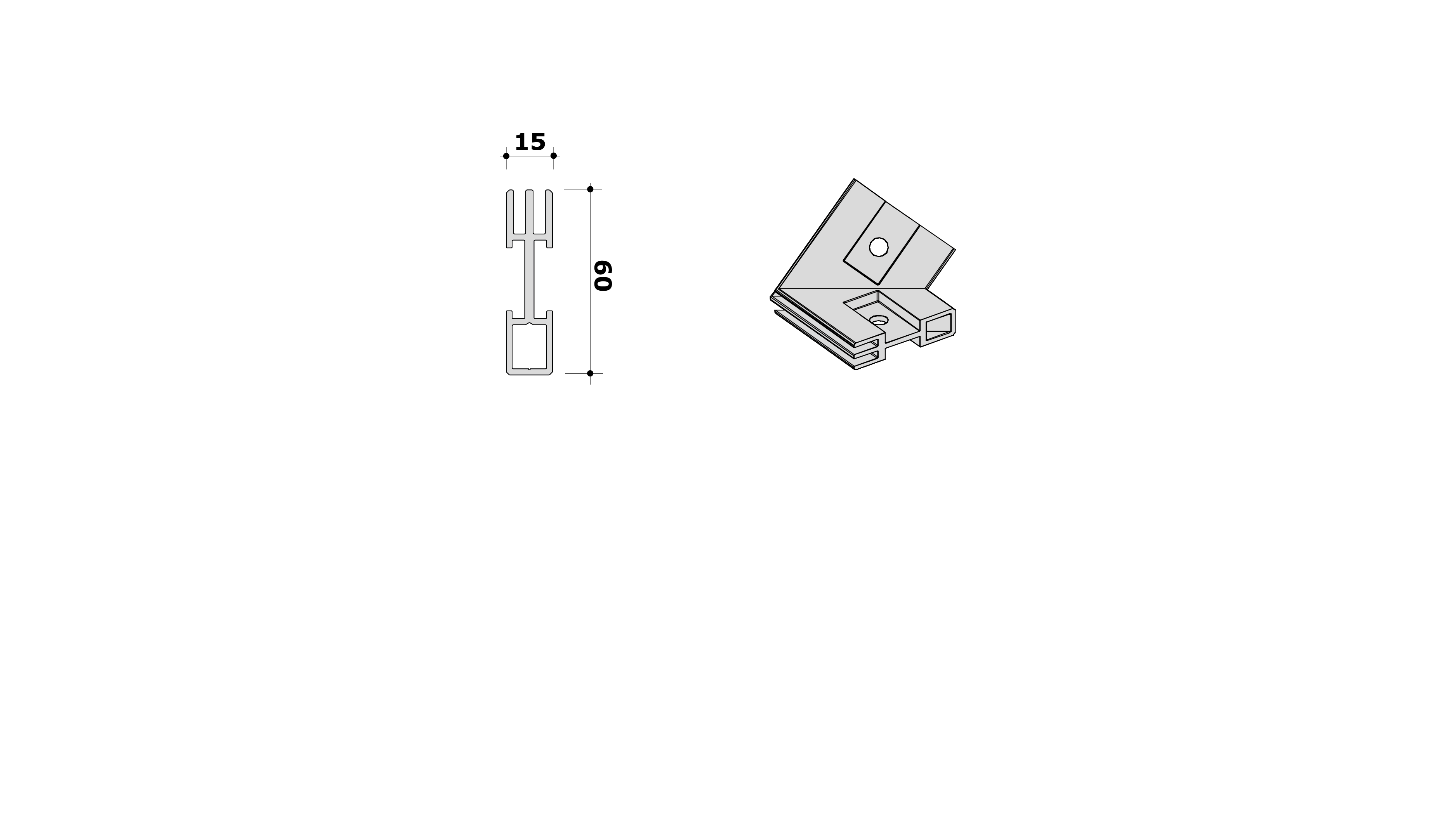

The system for easy manufacturing of cubes, cuboids, and complex bodies. A unique feature of the TRENDSTAND system are the die-cast full metal corners, which are connected by screws going through the keder profile. These metal corners provide for highest rigidity and allow for construction of very small as well as extremely big three-dimensional bodies.

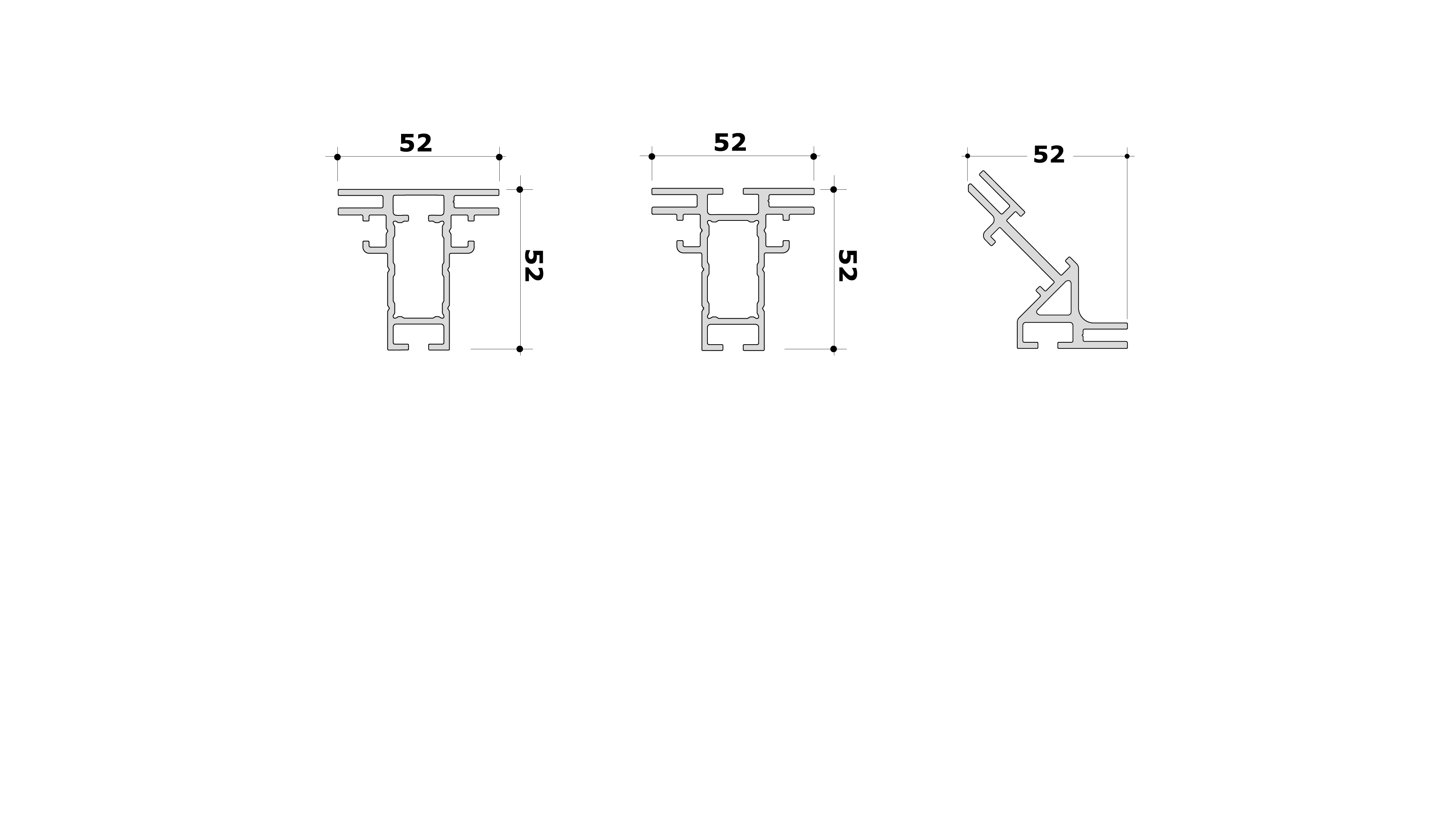

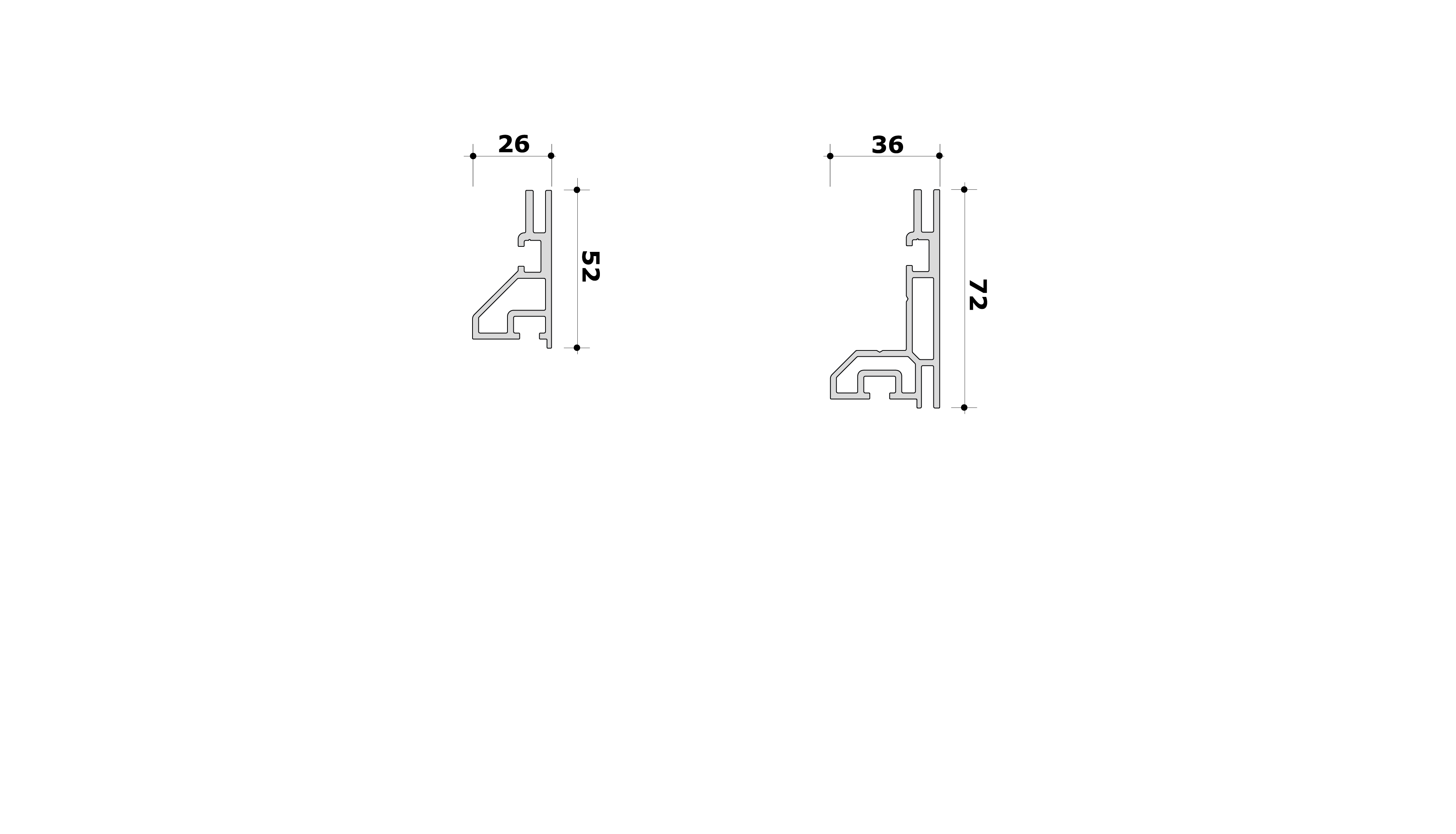

The fully compatible flat keder profile family for double-sided mounting of prints. T1 with a clean outside for visible edges, Y1 for simple mounting of feet and hanging devices at the bottom or the top of the frame, G1 for smooth corner solutions.

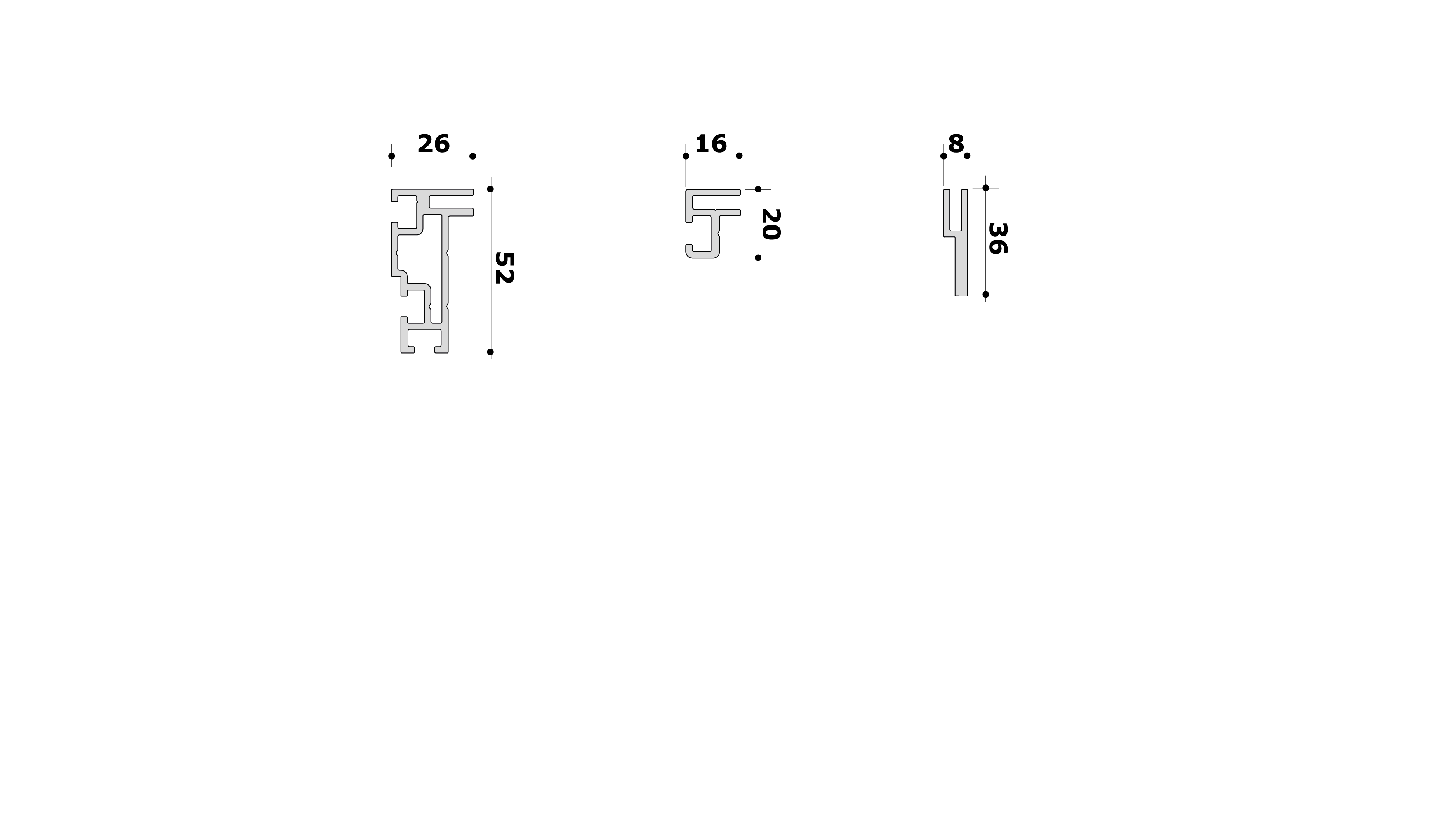

Our “simple” picture frame profiles. R1 is the stable variant and also suited for fixing a plate to its back. R2 is the economic alternative for small frames, but also suited for big frames with multi-pint fixing against a stable wall. R3 is a keder rail to be mounted into construction profiles. The drilling guide groove included in the R3 mirrors the groove dimension of the ALPHA, DELTA, and GAMMA profiles, so that digital prints can be attached to the supporting structure without a gap.

LED flat keder profiles for one-sided frames with full-area LED matrix backlighting. L1 is the slim variant for narrow LED spacing. L2 allows for wider LED spacing (-> price advantage) and—thanks to a second keder groove—can hold another, unlit fabric at the back of the frame.

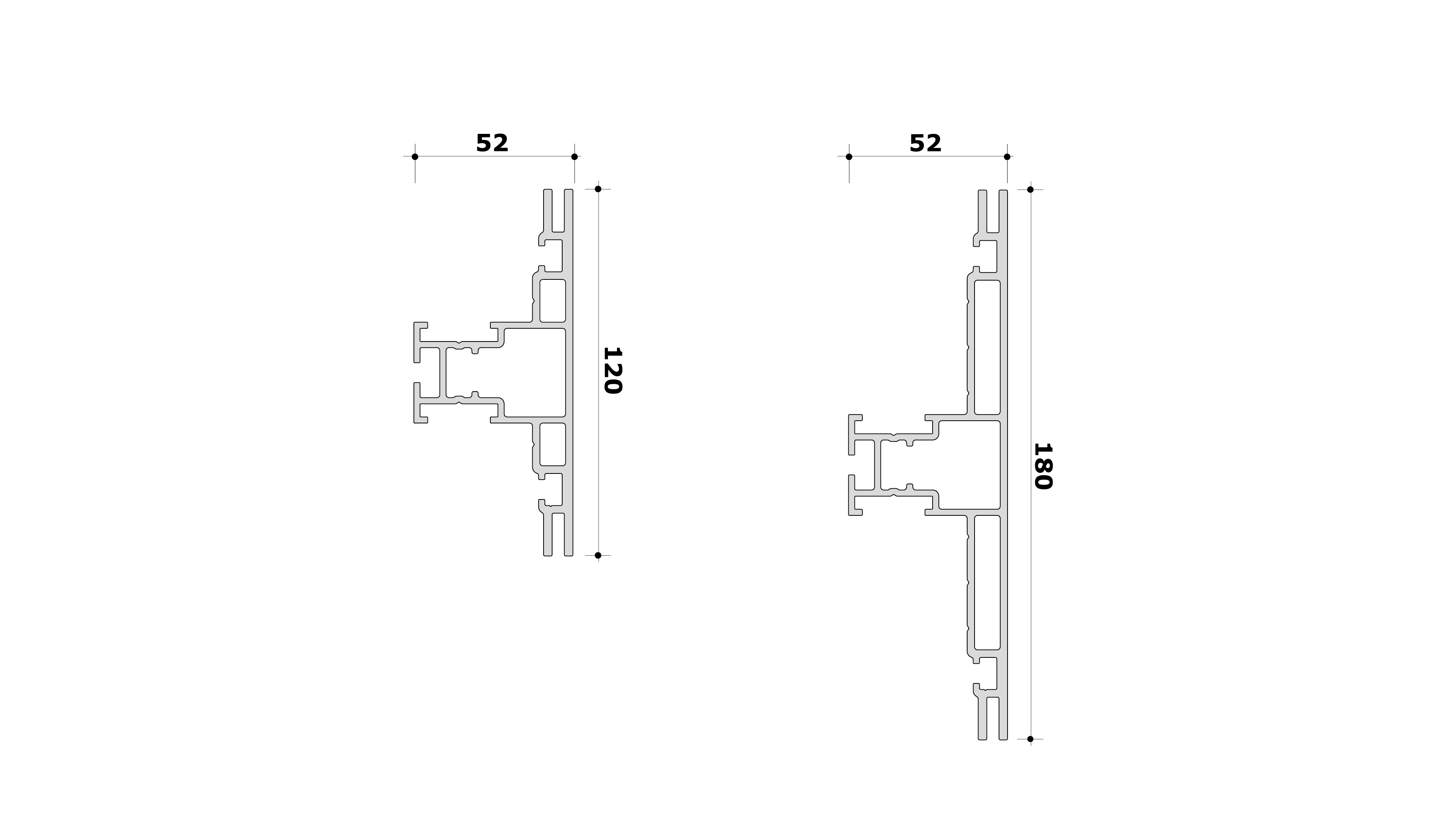

LED flat keder profiles for double-sided lightboxes in a slim (T3) and a wide (T5) version. As standard, both kinds of frame are lit by economic high power rim-feeder LEDs. For high-end applications it is also possible to work with full area matrix LEDs.

This post is also available in: German